Switchgear Retrofit Solutions

Switchgear Retrofit Solutions involves upgrading or replacing outdated components to enhance performance, reliability, and safety without needing a complete overhaul. This approach improves system efficiency and extends equipment life by integrating modern elements like protection relays, circuit breakers, or communication systems while minimizing downtime and costs. Retrofit solutions are cost-effective and ideal for facilities looking to improve operational efficiency, meet new safety standards, and accommodate increasing power demands without disrupting their existing infrastructure.

Explore our Products

Upgrade your power systems with our reliable and cost-effective switchgear retrofit solutions, designed to enhance performance and extend the life of your equipment.

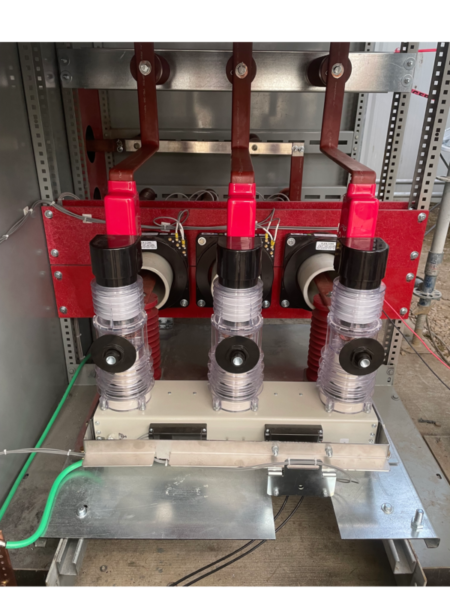

A picture of an abandoned 1200A 600V switchboard with missing breakers, doors, brackets, busbar, and more. Our complete retrofit solution was offered to restore it, saving both time and money.

The picture shows the fully restored internals of the switchboard, featuring new brackets, breakers, busbar, wiring, and instrument transformers.

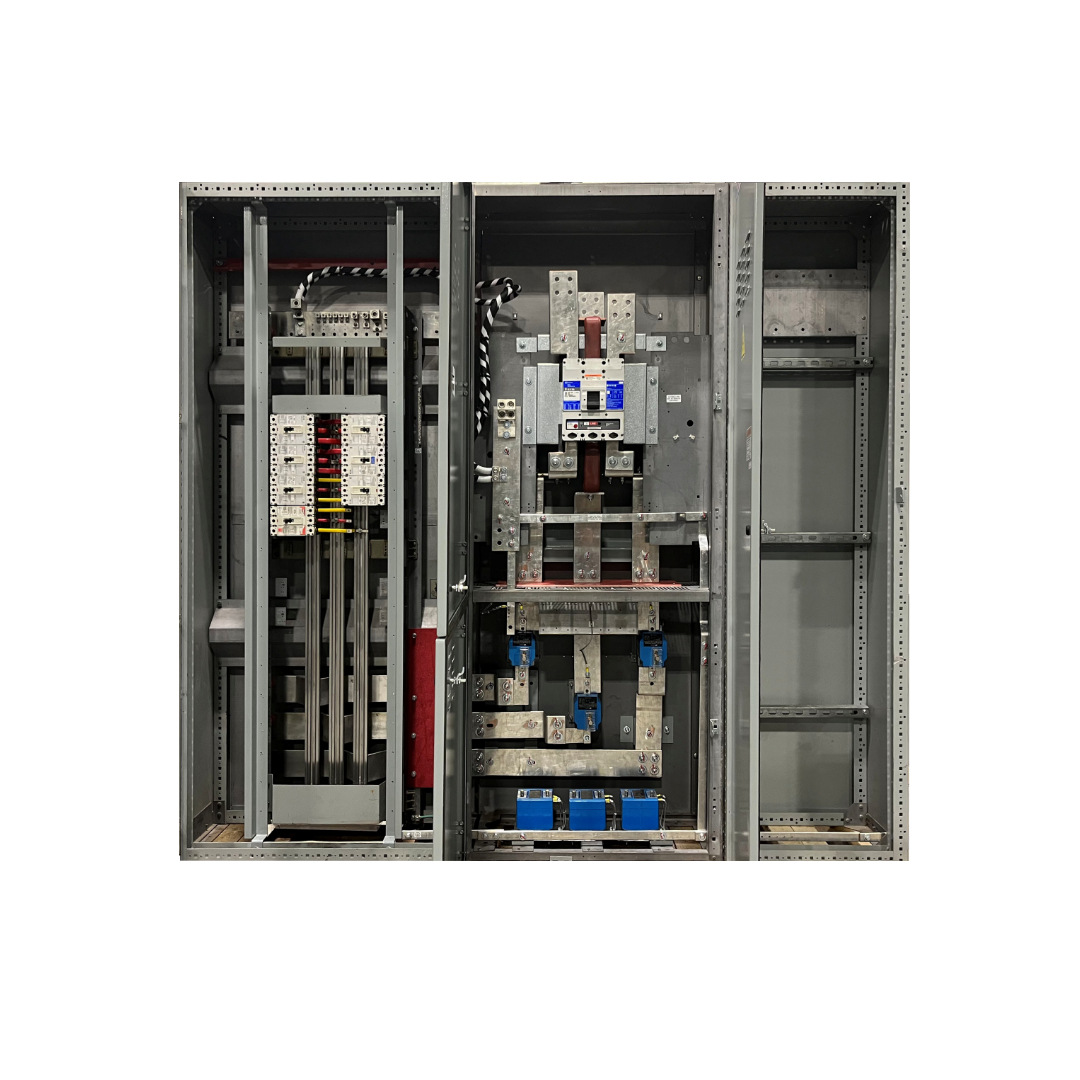

A new cabinet with breaker controls was added to the existing switchgear, reinforced with additional door hinges to support the extra weight. The cabinet was mounted using gaskets and sealant to ensure a leak-proof installation.

Inside view of the newly fabricated outdoor breaker control cabinet, featuring an inner door, breaker protection relay, controller, test switches, heater for moisture control, and a mechanical switch with brake cables for manual operation during power failure.

What is a Switchgear Retrofit?

Switchgear retrofit is upgrading or replacing existing equipment with modern components to improve performance, safety, and reliability. Instead of a complete replacement, retrofitting focuses on integrating modern technology, such as updated circuit breakers, protection relays, or control systems, into the current setup. This cost-effective solution extends the lifespan of the equipment, enhances system reliability and efficiency, reduces downtime, and ensures compliance with modern standards while minimizing operational disruptions.

Installation and Maintenance of Switchgear Retrofit

Switchgear retrofit installation and maintenance involve careful planning and execution to ensure seamless integration and compatibility with existing systems. During installation, skilled technicians assess the current switchgear setup, replacing outdated components with modern technology while minimizing downtime. Regular maintenance, including routine inspections, testing, and adjustments, is crucial to ensure that the retrofitted systems operate efficiently. This proactive approach helps identify potential issues early, extends the lifespan of the switchgear, ensures safety and reliability, and reduces the risk of failure.

Switchgear Retrofit Types

Switchgear retrofit types vary based on existing systems' specific needs and configurations. Standard options include circuit breaker retrofits, protection relay upgrades, and switchgear busbar modifications. Circuit breaker retrofits involve replacing old breakers with modern, more efficient ones. Protection relay upgrades integrate digital relays, offering enhanced monitoring, diagnostics, and protection. Busbar modifications address capacity and performance issues by upgrading the busbar system. These retrofits improve safety, system reliability, and operational efficiency without requiring complete switchgear replacement, making them a cost-effective solution for aging electrical systems.

Benefits of implementing Switchgear Retrofit Solutions

Implementing switchgear retrofit solutions offers numerous benefits, including improved safety, enhanced reliability, and increased system performance. By upgrading outdated components, facilities can better meet modern safety standards and reduce the risk of equipment failures. Retrofitting extends the lifespan of existing systems, delaying the need for costly replacements. Retrofitting minimizes the risk of system failures and unplanned downtime, enhancing operational efficiency. It is also a cost-effective alternative to full system replacement, ensuring compliance with current industry standards and regulations.