Power Junction Boxes and Splitters

At Solution Control Systems, we excel in delivering customized and dependable Power Junction Boxes and Power Splitters designed specifically for industrial applications. Our cutting-edge solutions provide seamless power distribution, ensuring maximum efficiency while adhering to the highest safety and performance standards. Built to withstand even the harshest environments, our products are engineered to offer superior reliability, whether in oil and gas, manufacturing, or other demanding sectors, ensuring long-lasting performance and reduced downtime for your operations.

Explore our Products

Explore our advanced power distribution solutions, including high-quality junction boxes and splitters, designed to meet your industrial needs with reliability, efficiency, and safety.

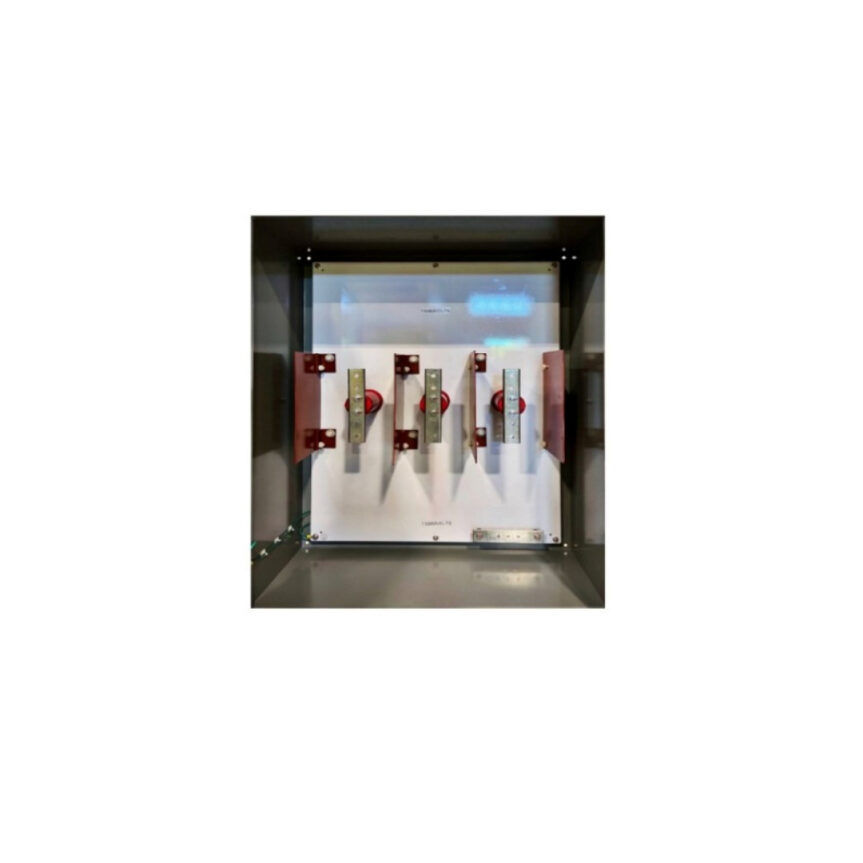

Pictures show 15kV 400A splice JBs in fibreglass enclosures featuring 15kV insulators and a 2" copper bus with holes for mechanical or compression lugs. The system includes door limit switches wired for a dry signal to the upstream breaker, which triggers a trip if opened while live.

The picture shows vibrant 5kV and 8kV JBs in International Orange and Signal Red. They are equipped with Posi Pin connectors, operated via hot stick for visual isolation, and have different sizes to prevent phase rotation. Safety features include ground checks, door limit switches, and external contacts to ensure de-energization and protect against accidents.

5kV splice junction box with 2-hole insulators, plastic partitions, pre-punched busbar, and ground bus. They are built for speed and cost-efficiency using standard enclosures. Optional features include mechanical lugs, large landing pads, nonferrous gland plates, IR windows, drain breather, and door limit switches for upstream breaker tripping.

What are Power Junction Boxes?

Designed for Durability and Safety

Our Power Junction Boxes are engineered to handle demanding industrial conditions. They offer protection for electrical connections while ensuring seamless power distribution. Each JB is built with high-quality materials and is designed to withstand harsh environments, including extreme temperatures, dust, and moisture.

Our JBs are featured under the following:

Weatherproof Designs: Available in NEMA-rated enclosures, ensuring protection in outdoor and hazardous conditions.

Customizable Configurations: We offer tailored solutions to meet your unique power distribution needs.

Multiple Applications: Ideal for oil & gas, manufacturing, power plants, and other industrial sectors.

Note: Our junction boxes comply with UL, CSA, and other industry standards, ensuring peace of mind and safe operations in any setting.

Key Features of Power Junction Boxes

- Robust, corrosion-resistant enclosures built for harsh industrial environments.

- Multiple entry and exit points for flexible cable management.

- Easy-to-access compartments for simplified maintenance and reduced downtime

- Suitable for both low and medium-voltage applications, offering versatile power distribution solutions.

Components of Power Junction Boxes

- Main busbar - a conductive metal bar that serves as the central point for distributing electrical power to multiple circuits, ensuring efficient power flow.

- Ground busbar - a common grounding point for all electrical components, ensuring safety by preventing electrical faults.

- Insulator standoffs - non-conductive spacers that support and isolate the busbars and other electrical components, preventing unintended contact and short circuits

- Lugs (optional) - heavy-duty connectors that attach cables to the busbars, ensuring secure and reliable connections for high current flow.

- Cable glands (optional) - protective entry and exit points for cables, preventing wear and damage while providing a secure, weatherproof seal for the wiring.

- Insulation barriers - insulating barriers that separate different voltage components, ensuring electrical safety by preventing accidental contact between live elements.

Low Voltage and Medium Voltage Power Junction Boxes

At Solution Controls, we offer Low Voltage (LV) and Medium Voltage (MV) Power JBs designed to meet the diverse needs of industrial power distribution systems. Our junction boxes provide reliable protection and efficient power management, ensuring seamless integration in complex electrical setups. Whether for LV systems up to 1,000V or MV systems up to 35,000V, our solutions provide seamless integration, enhanced safety, and efficient power distribution, supporting both low and high-demand industrial environments with precision and reliability.

Key Features of Low Voltage Power Junction Boxes

- Suitable for applications up to 1,000V

- Compact designs for easier installation and cable management

- Robust enclosures protect against environmental hazards

- Multiple connection points for flexible power distribution

Key Features of Medium Voltage Power Junction Boxes

- Engineered for voltage levels ranging from 1,000V to 35,000V

- Durable, corrosion-resistant materials to withstand harsh industrial conditions

- NEMA-rated enclosures for protection in outdoor and hazardous environments

- Customizable configurations to meet specific power distribution needs in MV networks

Types of Power Junction Boxes

- Weatherproof Junction Boxes: These boxes are designed for outdoor and harsh environments. They are NEMA-rated and protect internal components from dust, moisture, and extreme temperatures.

- Explosion-Proof Junction Boxes: built for hazardous locations, these boxes are designed to contain any sparks or explosions, preventing them from igniting flammable gases or dust in the surrounding environment.

- Underground Junction Boxes: These boxes are specifically designed for underground installations. They are used in utility, telecom and fibre optic systems, providing durable and long-lasting protection in tough conditions.

- Stainless Steel Junction Boxes: These boxes are used in corrosive environments. They offer excellent resistance to corrosion and ensure the longevity of electrical connections.

- Customizable Junction Boxes: These boxes are tailored to your requirements. They allow for custom configurations of entry points, terminal layouts, and materials to meet the unique needs of complex industrial power distribution systems.

- Compact/Wall-Mounted Junction Boxes: These are small, space-efficient junction boxes that can be wall-mounted. They are ideal for low-voltage and control applications in confined spaces or installations with limited room.

Benefits of Power Junction Boxes

- Enhanced Safety:

Power Junction Boxes protect electrical connections from environmental factors such as moisture, dust, and extreme temperatures, reducing the risk of electrical accidents and ensuring safe operations. - Organized Cable Management:

Junction boxes provide a structured way to manage and organize cables, helping to reduce clutter and making it easier to troubleshoot or modify systems when needed. - Durability and Protection:

These boxes are made from durable materials, such as stainless steel or thermoplastics, safeguard electrical connections against corrosion, physical damage, and other environmental hazards. - Customizable Solutions:

Junction boxes can be tailored to meet specific requirements, offering flexibility in entry/exit points, internal layouts, and materials to suit the application. - Ease of Maintenance:

Easy-to-access compartments in junction boxes simplify maintenance, enabling faster repairs and reducing downtime in critical industrial applications. - Regulatory Compliance:

Many junction boxes are designed to meet industry standards such as UL and CSA, ensuring that installations adhere to legal and safety requirements. - Improved Aesthetics:

Junction boxes can conceal and protect unsightly or potentially hazardous wiring, creating a cleaner, more professional appearance in industrial or commercial environments.

What are Power Splitters?

Our Power Splitters are engineered to efficiently distribute electrical power from a single source to multiple devices or areas, ensuring balanced energy flow and optimal performance. Designed for both small-scale and large-scale industrial applications, these splitters help maximize energy efficiency while maintaining smooth and reliable operations throughout your system. Whether managing high electrical loads or providing power to multiple points, our splitters deliver the performance and durability required for seamless power distribution.

Key Features of Power Splitters

- Efficient electrical power distribution from a single source to multiple devices or areas.

- High-load capacity for managing demanding industrial power needs.

- Versatile configurations to accommodate a wide range of connection types.

- Compact and space-saving design for easy integration into existing power systems.

- Built for durability and long-lasting performance in harsh industrial environments.

- Ensures optimal energy efficiency and balanced power distribution across all connected devices.

Components of Power Splitters

- Main busbar - a central conductive metal bar that distributes electrical power from the input source to multiple output terminals, ensuring balanced power distribution across the connected devices.

- Ground busbar - a common grounding point to ensure safe operation by protecting against electrical faults and ensuring proper system grounding.

- Insulator standoffs - non-conductive spacers that support and separate the busbars and other components, preventing accidental contact between conductive elements and maintaining electrical safety

- Lugs (optional) - heavy-duty connectors that attach cables to the busbars, ensuring secure and reliable connections to handle high current loads.

- Cable glands (optional) - entry and exit points that provide secure and weatherproof passage for cables into and out of the enclosure, protecting against wear, tear, and environmental factors such as dust and moisture.

- Insulation barriers - insulating components used to separate different voltage sections of the splitter, ensuring electrical isolation and preventing accidental contact between live elements.

Low Voltage and Medium Voltage Power Splitters

At Solution Controls, we offer Low Voltage (LV), and Medium Voltage (MV) Power Splitters are designed to efficiently distribute electrical power from a single source to multiple devices or areas in industrial applications. Whether you’re managing low voltage systems up to 1,000V or medium voltage systems up to 35,000V, our splitters ensure reliable and balanced power distribution to meet the needs of complex operations.

Key Features of Low Voltage Power Splitters

- Suitable for power distribution up to 1,000V

- Compact designs for easy integration into LV systems

- Multiple output configurations for versatile use

- High-efficiency power distribution to support smooth operations

Key Features of Medium Voltage Power Splitters

- Designed for systems handling up to 35,000V

- Robust, durable enclosures to withstand demanding environments

- Customizable options for complex industrial power setups

- Safe and efficient power splitting for high-demand MV systems

Types of Power Splitters

- Low Voltage Power Splitters: these splitters are designed for systems operating at voltage levels up to 1,000V, making them suitable for commercial and industrial environments that require the splitting of low-voltage power across multiple devices or systems.

- Medium Voltage Power Splitters: built for voltage levels ranging from 1,000V to 35,000V, these splitters are used in high-demand industrial applications like manufacturing plants, utilities, and power generation.

- Portable Power Splitters: used in temporary setups such as construction sites or outdoor events, these splitters allow for easy relocation and setup, providing flexible power distribution in areas that require mobility.

- Weatherproof Power Splitters: designed to operate in outdoor or harsh environments, these splitters feature weather-resistant enclosures and are typically used in industries like mining, oil & gas, and marine applications where environmental exposure is a concern.

- Rack-Mounted Power Splitters: compact and designed for mounting in standard equipment racks, these splitters are typically used in data centers or telecom environments, where space-saving and efficient power distribution are key.

- Industrial-Grade Power Splitters: heavy-duty splitters built for demanding environments, these are engineered to handle high electrical loads and are commonly found in factories, oil refineries, and large industrial complexes.

Benefits of Power Splitters

- Efficient Power Distribution:

Power splitters allow a single source to efficiently distribute electrical power to multiple devices or areas, optimizing energy usage and ensuring even distribution. - Space-Saving Solutions:

Power splitters eliminate the need for multiple power sources, reducing the number of cables and devices required, which is especially beneficial in compact installations or areas with limited space. - Cost-Effective:

By enabling a single power source to serve multiple devices, power splitters reduce the cost of installation and equipment, offering a more economical solution for power distribution. - Versatility:

Available in various configurations, power splitters can handle low and medium-voltage systems and are suitable for a wide range of industrial, commercial, and temporary applications. - Reduced Downtime:

Splitters allow for a more straightforward design of power distribution systems, which can help prevent overloads and ensure the smooth, continuous operation of connected equipment, minimizing downtime. - Scalability:

Power splitters provide flexibility in scaling systems up or down, allowing for easier expansion of electrical networks without requiring significant infrastructure changes. - Environmental Resilience:

Many splitters are designed to withstand harsh industrial environments. They provide protection from water, dust, and other external elements, ensuring reliable performance in tough conditions.

Both Power Junction Boxes and Power Splitters offer essential advantages in ensuring safe, efficient, and reliable power management, particularly in industrial and commercial settings.