Protection and Monitoring Solutions

Our advanced protection and monitoring solutions are meticulously engineered to safeguard critical equipment, providing robust defence against potential hazards and operational interruptions. Designed to support various industries, these solutions enhance safety, extend equipment lifespan, and maintain continuous, reliable operation across diverse industrial environments. By tailoring each solution to your facility's unique requirements, we deliver targeted protection that minimizes downtime and maximizes productivity, allowing your operations to perform at peak efficiency. From preventing electrical faults to enabling predictive maintenance through real-time monitoring, our solutions are crafted precisely to support your operational goals and promote a safe, optimized work environment.

Explore Our Products

Explore our industry-leading protection and monitoring solutions, designed to safeguard your equipment, ensure continuous operation, and enhance workplace safety with advanced, customizable technology.

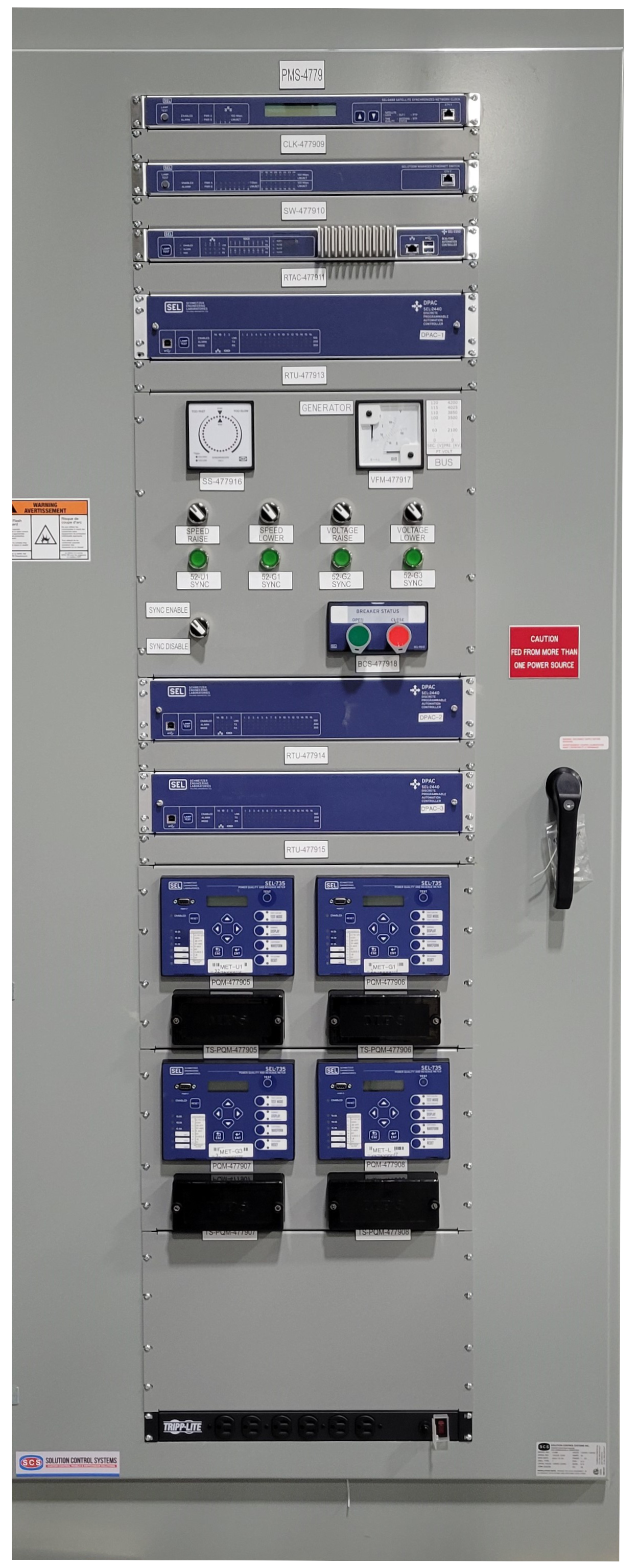

Sync Control Panel

This industrial control panel features multiple labelled components. Components include controllers, protection, metering and networking devices for optimal performance and reliability. The panel includes control buttons for functions like "Speed Raise," "Voltage Raise," and a "Breaker Status" indicator, along with digital and analog meters for real-time monitoring of parameters such as generator and bus voltages.

Protection Control Panel

This relay panel is structured with SEL relay modules at the top for monitoring and protective relaying. The switches labeled "Local/Remote" and "Control Switches" allow toggling between operational modes and controlling functions. Test and isolation switches provide maintenance and safety options. The bottom section includes terminal blocks for "Current & Breaker Alarms" and "Trip Close" functions, organized for monitoring and alarm circuits.

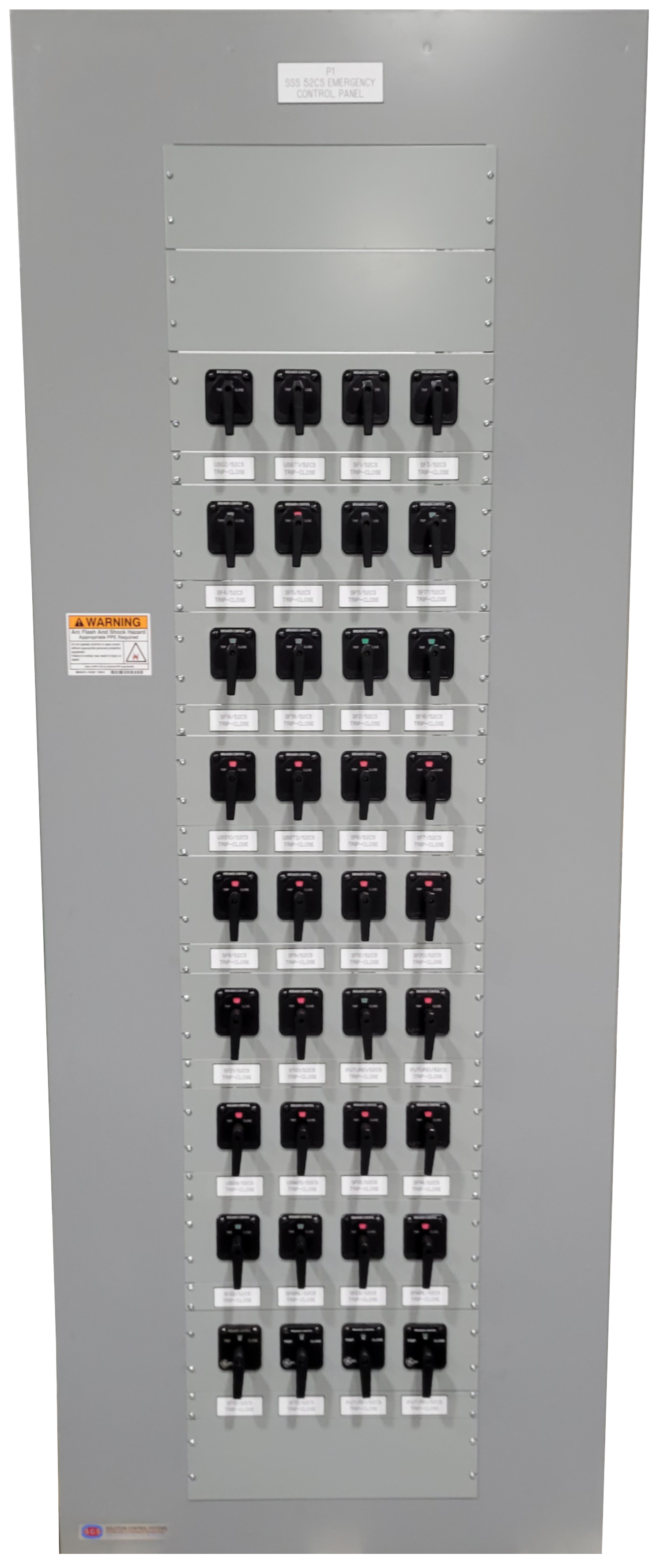

Breaker Control Panel

This breaker control panel features multiple rows of labelled control switches, each assigned to a specific circuit or equipment for quick emergency management. A safety warning on the side emphasizes its critical role, and the compact design allows numerous controls to be housed efficiently within a single panel.

Sync Control Panel

A protection control panel integrated with some rack-mount and door-mounted devices. The door-mount devices are fitted on 19” blank plates and mounted on the rack opening. A standard free-standing enclosure was converted to a rack-mount enclosure by fitting a rack-mount plate in the rear and cutting the enclosure's back wall. This is a cost-effective and fastest way to get a rack-mount cabinet.

Protection Control Panel

Door mount protection and control devices mounted on rear wall of custom cabinets which came with all the cutouts. This also can be achieved on a standard cabinet by supplying a flat plate with cutouts and removing the back of the enclosure by cutting

Breaker Control Panel

Solution Control Systems can modify the standard enclosures to rack mount enclosures by fabricating a rackmount plate in the rear. By removing the back wall of the enclosure. This is a cost effective and fastest way to get a rack mount cabinet.

Sync Control Panel

Customer manufactured plates and doors to replace the old ones, fitted with protection relays, breaker switches, test switches and pilot lights to retrofit the existing switchgear controls. All the devices pre-wired and a pig tail provided for connection to the breakers and other equipment.

Protection Control Panel

Training and testing modules are fabricated with rack-mounted and door-mounted devices. The protection relays, lights, and switches are mounted in the rack or the filler plates and housed in hard shell cases with removable covers for the front and back. The cases are stackable, light, easy to carry around, provide maximum protection to your equipment, and are easy to deploy.

Breaker Control Panel

SEL protection and control relays mounted in rack mount cabinets with prewired to test jacks, push buttons and pilot lights on a rack mount plate. These are training modules built in portable hard-shell cases which are easy to transport and can be stacked on top of each other for an easy deployment in training rooms or sites.

Dual access free standing data cabinets c/w network switches, uninterrupted power supplies, power distribution terminals and power distributions bars. Non-rack surface mount devices mounted on special rackmount adapters

A small cabinet with a 10 deck 40 breaker control switch wired back to terminals for some analog and digital signals going to control relays for selection between generator and utility power.

What is Protection and Monitoring?

Protection and monitoring involve systems and strategies designed to safeguard industrial equipment and ensure continuous, reliable operation. Protection solutions prevent damage from electrical faults, overloads, and environmental risks, while monitoring systems provide real-time data on equipment health and performance. Together, they help identify potential issues early, allowing for preventive maintenance, reduced downtime, and extended equipment lifespan, ultimately optimizing operational safety and efficiency.

Comprehensive Equipment Protection

- Overload and Short Circuit Protection - Our advanced overload and short circuit protection systems are designed to detect when power thresholds exceed safe levels. These systems automatically disconnect power, effectively protecting critical equipment and preventing severe damage.

- Arc Flash Protection - Arc flash incidents are among the most dangerous electrical hazards. Our cutting-edge arc flash protection devices detect early signs of arc flash events and instantly deploy mitigation measures, minimizing risks and protecting personnel and equipment.

- Overcurrent and Earth Fault Protection - Enhance the safety and stability of your operations with overcurrent and earth fault protection solutions. These systems maintain electrical balance, reducing the risk of faults and ensuring operational continuity in high-demand environments.

Advanced Monitoring Capabilities

- Real-Time Equipment Monitoring - With real-time monitoring, track equipment health consistently to identify irregularities early, proactively address potential issues, and optimize operational performance.

- Thermal and Vibration Analysis - Thermal and vibration analysis detects early signs of wear and mechanical stress, allowing timely interventions that prevent unexpected breakdowns and costly downtime.

- Environmental Condition Monitoring - Ensure optimal operating conditions for your equipment with advanced environmental monitoring, tracking temperature, humidity, and dust levels to maintain stable performance and extend equipment lifespan.

Custom Protection and Monitoring Panels

Our custom protection and monitoring panels are designed and manufactured to meet the specific needs of each operation. They integrate multiple protection and monitoring features into a single, cohesive solution. These panels simplify system integration, enhance reliability, and reduce space requirements, offering a comprehensive approach to equipment protection.

- Integrated Protection Systems - Benefit from a seamless combination of essential protection features—such as overcurrent, undervoltage, and frequency protection—within one unified panel, ensuring robust, consistent safety for critical systems.

- Customized Monitoring Solutions - Our monitoring solutions, with flexible configurations, adapt to your unique operational requirements. They offer real-time data tailored to optimize system performance and streamline maintenance strategies.

Enhanced Safety with Comprehensive Protection Mechanisms

Safety and reliability are critical in every industrial setup. Our range of protection mechanisms is designed to prevent electrical mishaps and ensure the safety of both equipment and personnel.

- Transient Voltage Surge Suppression (TVSS)

Protect sensitive equipment from voltage spikes with our TVSS solutions that absorb excess voltage, preventing damage and maintaining power quality. - Phase Failure and Sequence Protection

Avoid equipment damage due to phase loss, phase reversal, or phase imbalance. Our phase protection systems detect these conditions early to keep operations running smoothly. - Undervoltage and Overvoltage Protection

Safeguard equipment from voltage fluctuations that could disrupt operations or lead to costly repairs. Our systems automatically detect and mitigate risks associated with voltage variations.

Intelligent Monitoring for Predictive Maintenance

Stay ahead of equipment failures with our predictive maintenance monitoring solutions. Real-time data provides insights to help you make informed maintenance decisions, reducing unexpected downtimes.

- Condition Monitoring with Smart Sensors

Our intelligent sensors track multiple variables, such as temperature, pressure, and humidity, enabling you to monitor the health of critical assets continuously. - Data Logging and Trend Analysis

Collect and analyze historical data to identify trends that indicate potential future issues. Trend analysis helps plan proactive maintenance to prolong equipment life. - Energy Monitoring and Optimization

Track energy usage across systems and identify opportunities for reducing energy consumption, contributing to operational efficiency and sustainability.

Emergency Power and Battery Backup Monitoring

Ensure critical systems remain operational during power disruptions with dedicated emergency power and backup systems monitoring.

- Uninterruptible Power Supply (UPS) Monitoring - Monitor UPS status and battery health in real-time, ensuring they’re ready to provide backup power when needed.

- Battery Condition Monitoring - Protect against battery failure with monitoring systems that track battery health indicators like voltage, temperature, and charge cycles.

- Automatic Transfer Switch (ATS) Monitoring - Track ATS status to ensure seamless transfer to backup power during outages, preventing disruption of critical operations.

Environmental and Ambient Condition Monitoring

Many industrial applications rely on specific environmental conditions. Our solutions monitor and maintain optimal conditions to prevent external factors from affecting equipment performance.

- Temperature and Humidity Control

Real-time monitoring of temperature and humidity levels prevents overheating or excessive moisture, which can lead to equipment failure. - Dust and Particulate Monitoring

Monitor dust levels in the environment, especially in industrial settings, to reduce the risk of contamination and maintain air quality. - Corrosion Monitoring

Detect early signs of corrosion on critical equipment, ensuring timely intervention and preserving the integrity of equipment in harsh environments.

Fault Detection and Diagnostics

Accurate fault detection and diagnostics ensure any issues are identified swiftly, enabling you to take corrective actions before small issues become large problems.

- Event Logging and Fault Recording

Keep a record of faults, events, and disturbances for post-event analysis and compliance with safety standards. - Root Cause Analysis (RCA)

Perform thorough investigations into fault events to determine the root cause, enabling long-term solutions and preventing recurrence. - Self-Diagnostic Capabilities

Utilize self-diagnosing equipment that can identify and report its own faults, helping technicians quickly address issues without complex troubleshooting.