Electrical Control panels require regular maintenance but at some point, these panels require replacement, make sure whenever you chose to buy a control panel it is built by a reputed industrial control panel manufacturer.

What Does an Electrical Panel Do?

Different control panel have different purposes, but most electrical control panels distribute power, control, protect and monitor equipment. An electrical control accepts the power from a power source like a utility panel board or generator and distribute with in the control panel with a use of circuit protection device like a breaker or fuse. Then that power runs through a power switching device like a power relay, contactor, soft starter, variable frequency drive and control the intended equipment in the field.

Electrical control panel takes commands from switches, human machine interface screens, programmable logic controllers, timers installed within the control panel or from sensor, limit switches installed on the controlled equipment. Industrial control panel manufacturers always make sure the control panel is designed as per requirement and tested for its operation.

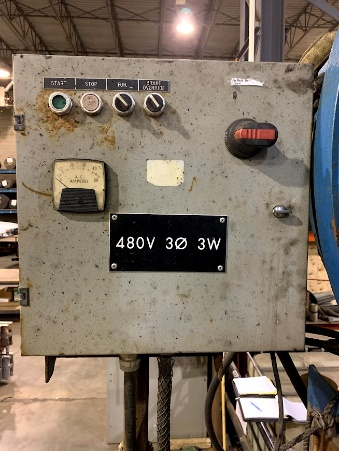

- Electrical control panel is too old and has outdated components.

- It has frayed, damaged wires, loose connections, messy wiring, open live parts.

- It is looking rusty, has a water damage and door doesn’t close properly.

- Seeing sparks and smoke inside.

- Hearing unusual noises from the internal components.

- Unusual noise from motors or any other loads powered by this control panel.

- Door mounted components or internal components broken.

- Markings and warnings are worn off and unable to read.

- Burning smell coming from components due to overheating

- Breaking down too often and requiring maintenance all the time.

Key Signs That You Should Consider Replacing Your Electrical Control Panel

1. Your Panel Doesn’t Use Breakers

Breakers or most often called circuit breakers protect current carrying conductors and equipment from over current situations. There are lot of different type of circuit breakers out there, but the most common circuit breakers are miniature circuit breakers, molded case circuit breakers, air circuit breakers and vacuum circuit breakers. When over current reaches a pre-set value or time these circuit breakers trip and isolate the downstream circuit to eliminate shock and fire hazard. At the same time circuit breakers provide local disconnection means for troubleshooting and maintenance. The biggest advantage of circuit breakers is that these can be reset after the trip when fault current is cleared. Due to all these reason control panels must have circuit breakers in them or beside in another panel. If your panel doesn’t have circuit breakers or any other type of over current protection, it is recommended that you have it upgraded by a licensed panel shop as soon as possible.

2. Circuit Breakers Are Tripping Frequently

There are number of reasons circuit breaker can start tripping in the control panel:

- Most common reason

- Circuit breakers getting very old.

- Malfunctioning circuit breaker or other component of the electrical system

- Insulation of current carrying conductors deteriorating

- Overloading of connected equipment

- More equipment added to existing circuit.

- Short circuit or electrical fault in the wiring or in equipment

- Wiring size or distance changed in circuit.

- Input voltage changed.

- Temperature changed

- Loose connections

- Ground Fault in the System

- Over or under voltage

- Moisture or water ingress

- Shunt trip circuit faulty

- Settings changed on the circuit breaker.

- Type of load changed.

3. Your Electrical Panel is Rusted or Broken

Your electrical panel is heart of power distribution in your facility or plant. A rusted or broken electrical panel indicates water or moister ingress, mechanical and electrical damage to panel enclosure and internal components. This can create safety issues like shock hazard, fire hazard or issues like power outage, property damage or loss of production.

If your control panel has these damages, it is important to have it inspected by qualified personnel from a panel shop and follow the instructions from them.

In some cases, it can be repaired on site by fixing the broken damage and in other cases this need to be sent to panel shop for complete retrofit or replace the whole panel.

It is recommended get the regular maintenance on electrical panels by qualified personnel, so it is not too late where there is a chance for power outage.

Also Read: Power Distribution Center: What Is Important To Consider?

4. Not Enough Outlets

Sometimes you need to plug or wire more things to a control panel or a power distribution panel, and it may not have enough outlets or circuits or capacity to do so. At this point control panel must be assessed by qualified personnel and provide you a report for the best way to upgrade. Most importantly the assessor needs to review the panel design, fabrication, and wiring, at the same time he needs to verify the power source and the load equipment.

After all this has been reviewed, he can suggest you the best plan of action. You may be fortune enough that the panel supplier provided spare circuits for future loads otherwise you could be looking at following upgrades.

Power source or breaker upgrade may require.

Panel may be upgraded with retrofitting new components.

Panel may need a replacement with a new one.

5. Smells Like Something Is Burning

If you come across smells like something is burning around electrical equipment this could be a very serious issues like overlading of electrical components, short circuits or loose connections. In some cases, it could be just varnish odors of the coils of new equipment like transformer or reactors.

To verify what kind of this smell is, equipment should be immediately evaluated by qualified personnel, If safe and possible, de-energized the power source as soon as possible to avoid the fire, shock and property damage.

Evaluator need to asses the whole circuit including the power source, electrical panel and the load equipment. If he sees obvious damage within the circuit anywhere, those parts need replacement and further evaluation for the cause. There may be a design change or component replacement, or calibration required to eliminate the cause.

6. You See Sparks When Plugging Things In

When you see sparks when plugging things in, there could be shorts in the wiring or in the item itself you are plugging in or loose wiring any where in the circuit. Do not try to plug or unplug items and turn off the main disconnect if possible. If you see any obvious damage in the item you were trying to plug in, that could be one of the reasons for sparks and if unplugging that item eliminates the sparks seems like the issue has been fixed but in either case, we recommend getting it checked from electrician or qualified personnel.

Also Read: Understanding the Core Components of a Control Panel

7. You’re Installing or Upgrading Large Appliances

If you are planning to upgrade large equipment or appliance in your facility very first thing you should look at the power requirement of new items and what you have available. For this exercise you may need a qualified electrical contractor, engineer or a consultant. Now the questions is, if the new equipment is being fed from existing control panel or power distribution panel or totally from a new panel. Now your contractor, engineer or consultant will look at the input voltage and power requirement of the new equipment and evaluate if you can run this on existing panel or you need a new panel or you may need a service upgrade.

8. Buzzing Sounds Coming from the Breaker Box

Buzzing sounds coming from a breaker box or a control panel can indicate a serious problem with in the electrical box or circuit system and should be addressed promptly by a qualified personnel. There are many reason you could hear a buzzing sound from the breakers but most common reasons as following

It can be caused by loose connections, overloading of circuits, or faulty breaker, faulty circuit or faulty load equipment or interference from other circuits.

There are certain steps required to trouble shoot the cause and fix the issue but it should all be performed by qualified personnel.

9. Lights are Flickering or Dimmer than Usual

Lights flickering or dimming can happen due voltage drop in an electrical circuit sometimes this could be simple as, loose connections, faulty light fixture or during a start-up of large equipment especially a motor connected in the same circuit or with in the same distribution panel. There are few other reasons for this issue

- These lights are newly connected to an already overloaded loaded circuit.

- The conductors are not sized properly and may be the distance is too long which causes a voltage drop and lead to flickering & dim of lights

- Possible intermittent shorting happening in the circuit.

- Sometimes this can happen due to interference of high harmonic signals from vfd output circuits as well.

It is recommended that you contact qualified personnel and have this checked.

10. The Wrong Amp Wiring

Using the wrong amp or size wiring can cause a number of problems, Mostly the problem will happen if the wire size is smaller than the one required.

This can cause a damage to your complete electrical system, conductors can start heating up and pose a fire hazard, the connected devices can also be damaged due to voltage drop and create a risk of fire. To avoid all these issues, it is important to use the correct amp size wiring for the electrical load and equipment you are working with. If you are unsure about the proper wiring for your electrical system, it is best to consult a qualified personal for assistance.